When 'Shipped' Doesn't Mean Shipped: The 3PL Definition Problem

A 3PL owner on Reddit said it best: “3PL SLAs vary - some are 24-48 hours, and some are a cutoff. For us, it’s a 12pm cutoff for same day orders on pickups.”

This is the dirty secret of fulfillment metrics: nobody agrees what anything means.

The “Shipped” Problem

Ask five 3PLs when an order is “shipped” and you’ll get five different answers:

- 3PL A: When we generate the shipping label

- 3PL B: When the package is physically packed

- 3PL C: When it’s on the dock ready for pickup

- 3PL D: When the carrier scans it at our facility

- 3PL E: When the carrier’s tracking shows the first scan

One merchant told us they switched 3PLs and their “on-time shipping” dropped from 98% to 73% overnight. Did service get worse? Nope. The new 3PL just measured differently.

Real Examples from the Field

The Label Generation Game

Some 3PLs mark orders as “shipped” the moment they print a label. Great for metrics, not so great when that box sits on a pallet for two more days. We’ve seen packages with Monday labels that don’t move until Wednesday.

The Cutoff Confusion

“Orders placed before 2pm ship same day!”

But what does that mean?

- Cut by 2pm, labeled by 5pm, picked up tomorrow?

- Cut by 2pm, out the door by 5pm?

- Cut by 2pm, carrier has it by midnight?

One 3PL’s “same day” is another’s “next day.”

The Carrier Scan Delay

Here’s a fun one: Your 3PL hands packages to UPS at 4pm. UPS doesn’t scan them until the next morning at their hub. When did it “ship”? The 3PL says 4pm. Your tracking says next day. Your customer is confused.

Why This Matters More Than You Think

Customer Expectations

Your customer sees “shipped” and expects movement. When tracking shows nothing for 24 hours, they blame you, not definitions.

Comparing 3PLs

That RFP where everyone claims 99% on-time shipping? Meaningless without definitions. You’re comparing fiction.

SLA Penalties

If your contract says “ship within 24 hours” but doesn’t define “ship,” you’re asking for disputes.

Questions to Ask Your 3PL (or Prospect)

Get specific. Painfully specific.

Processing Time

- When does the SLA clock start? Order placement? Payment cleared? After fraud review?

- What’s your actual cutoff time for same-day processing?

- How do you handle orders that come in at 11:59am vs 12:01pm?

Shipping Definitions

- What system status triggers “shipped”?

- How long between label creation and carrier pickup?

- Do you pre-generate labels? When?

Carrier Handoffs

- What time does each carrier actually pick up?

- How long until first carrier scan typically?

- What happens if carrier misses pickup?

Peak Season Changes

- Do cutoff times change during Q4?

- How much do carrier pickup delays affect you?

- What’s your real capacity vs. standard SLAs?

The Data You Actually Need

Forget their definitions. Track what matters to customers:

Order-to-Door Time: From checkout to delivery. Everything else is noise.

Carrier Scan Time: From “shipped” status to first carrier scan. This reveals the gap.

Promise vs. Reality: What you tell customers vs. what happens.

How to Standardize Across Multiple 3PLs

If you’re using multiple 3PLs, create your own definitions:

Define “Processed”

Order picked, packed, and labeled. Not just “started” or “in queue.”

Define “Shipped”

In carrier’s possession with first scan confirmed. Not just “ready for pickup.”

Define “On-Time”

Meeting the delivery promise shown at checkout. Not the 3PL’s internal SLA.

Track Everything

- 3PL’s “shipped” timestamp

- First carrier scan timestamp

- Actual delivery timestamp

- Calculate the gaps

The Two-Layer Solution

Here’s the approach that actually works: track both.

Layer 1: Track Against Their SLAs

Your 3PL says they ship same-day with a 2pm cutoff? Fine. Track that. Hold them to THEIR definition. If they say “shipped” means label created, track label creation. You can’t penalize them for missing SLAs they never agreed to.

Layer 2: Track What Actually Matters

But also track the real metric: when the carrier takes possession. This is the moment that matters for customer experience. Once it’s in UPS’s hands, your 3PL has done their job. Everything before that is internal process.

Why You Need Both Views

For 3PL Accountability: Track their SLA their way. Did they create labels by their cutoff? That’s their commitment met.

For Customer Reality: Track carrier handoff. That 24-hour gap between “label created” and “carrier pickup”? That’s what customers feel.

For Comparison Shopping: When evaluating 3PLs, ignore their SLA definitions. Compare carrier handoff times. That’s apples to apples.

The Best Practice Stack

- Let each 3PL define their SLAs (2pm cutoff, label creation, whatever)

- Track performance against those definitions (fair is fair)

- Also track carrier handoff (the universal truth)

- Show both metrics but make decisions on carrier handoff

- Set customer expectations based on carrier handoff, not 3PL SLAs

Your 3PL hit 100% of their SLAs but packages sit for 2 days before pickup? The SLA isn’t wrong, but it’s not useful either.

How 3PL Pulse Actually Handles This

Here’s exactly how we solve this in our platform:

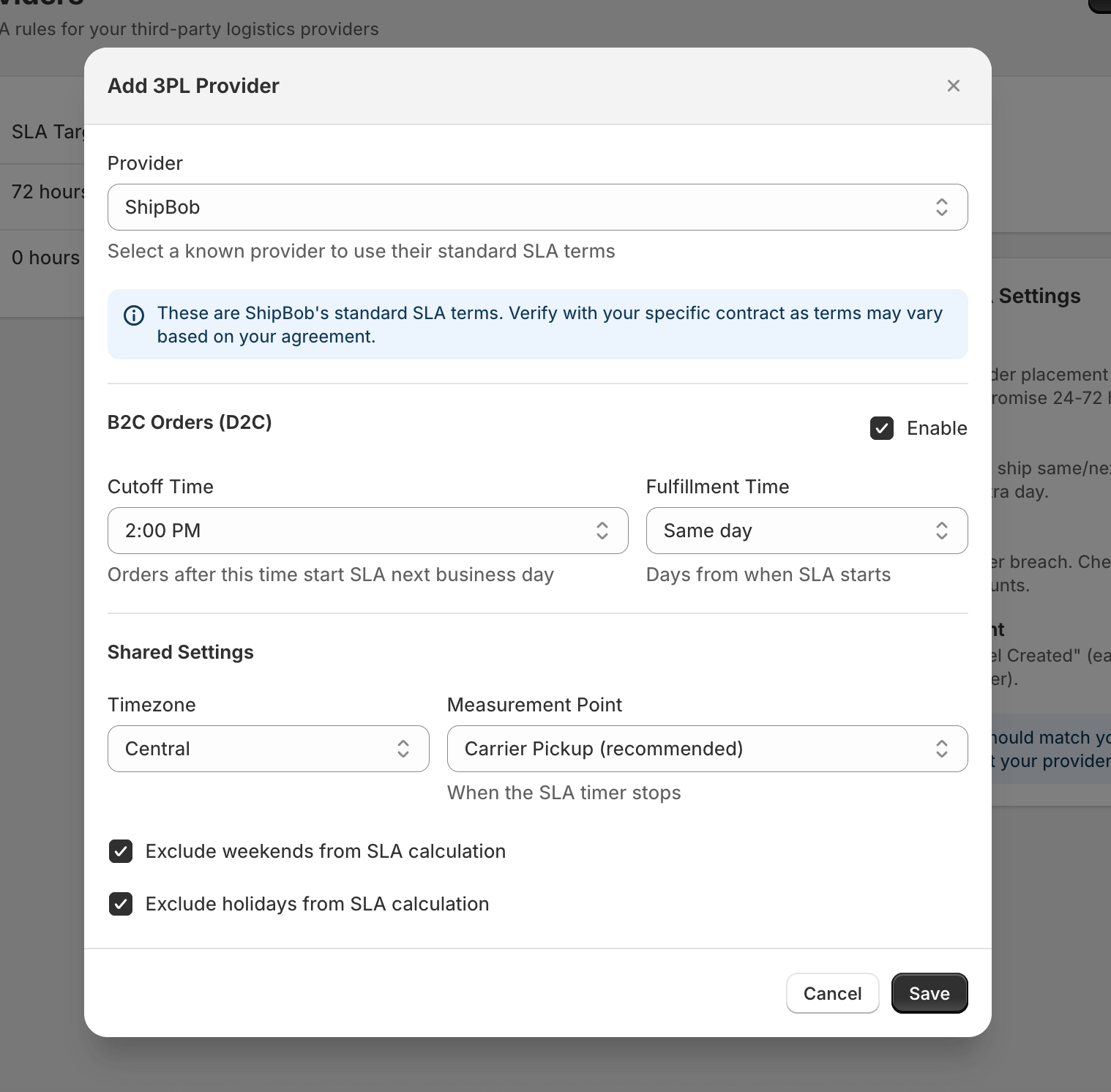

Step 1: Configure Their Specific SLAs

For each 3PL, you set:

- Cutoff Time: “2:00 PM” (or whatever they promise)

- Fulfillment Time: “Same day” or “Next day” (their commitment)

- Their Timezone: Because 2pm EST vs PST matters

- Credit Per Breach: Track the financial impact

Configure each 3PL's specific SLA terms in 3PL Pulse - set cutoff times, fulfillment promises, and measurement points to accurately track performance

Step 2: Choose Your Measurement Point

This is the key. You can pick:

- “Label Created” - If that’s what your 3PL’s contract says

- “Carrier Pickup” (recommended) - When it actually matters

- “First Carrier Scan” - For ultimate verification

We recommend Carrier Pickup because it’s the moment your 3PL loses control and the carrier takes over. It’s the universal truth across all providers.

Step 3: Get Both Views

Your dashboard shows:

- SLA Performance: Based on their definitions (fair to them)

- Actual Performance: Based on carrier pickup (reality check)

- The Gap: How long between “their shipped” and “real shipped”

Now you can have an honest conversation: “You’re hitting your SLAs 98% of the time, which is great. But there’s a 36-hour average gap before carrier pickup. Can we work on that?”

Want to see how your 3PLs really perform? 3PL Pulse lets you configure each provider’s specific SLA terms while also tracking the metrics that actually matter. Because understanding the difference between “technically shipped” and “actually shipped” shouldn’t require a philosophy degree.